2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

Mould manufacturing

Introduce

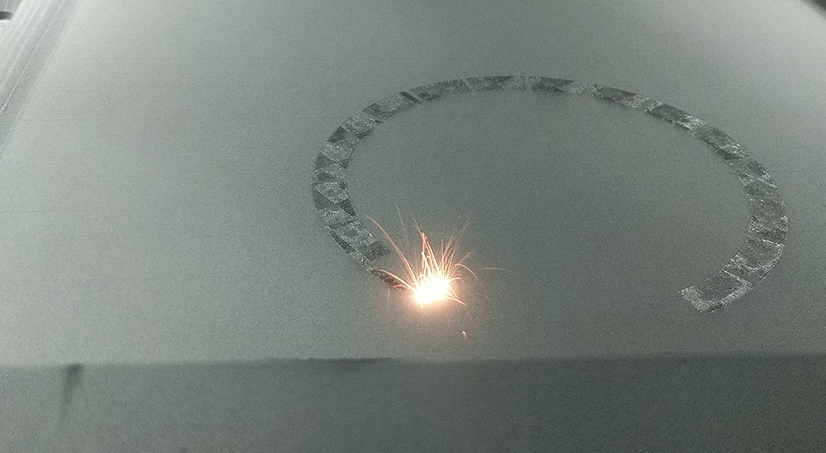

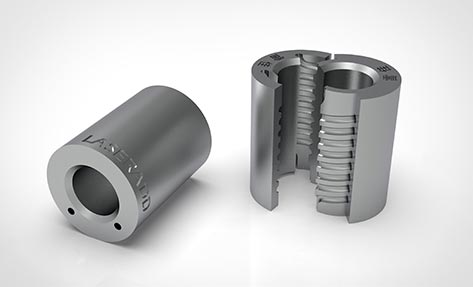

AEROSPACE

As an important means of modern manufacturing technology, mold plays an extremely important role in the mass production and manufacturing of automobiles, electronics, consumer goods, household appliances and so on. Traditional die manufacturing processes such as NUMERICAL control machining, edM, precision casting, etc., have been widely used for a long time. With the continuous improvement of product quality requirements, traditional manufacturing technology is increasingly difficult to meet the quality requirements of high-end precision molds. Because of 3 d printing technology won't be in the process of manufacturing products internal structure and shape of the complex constraints, complex accompanying by inside the mold cooling waterway design and processing, 3 d printing technology can easily achieve high-end mold manufacturing, metal application of 3 d printing technology makes the design of the mold highly flexible, easily implement complex structure, The realization of scale customization, from design to direct production of digital products, drives the production of mold products to customization and complexity.

Advantages of 3D printing

- Any special complex structure with shape cooling waterway design can be easily presented. Improve cooling efficiency and consistency, ensure uniform shrinkage of products, improve product quality, effectively reduce warpage deformation, cracking flay, bubble trachoma and other product defects, significantly improve mold product quality and yield, prolong mold service life and reliability, reduce production costs. A small amount of processing allowance, reduce the material consumption and machining time, shorten the mold manufacturing cycle.

- Damaged molds can be repaired or modified into molds with conformal channels by 3D printing. For some complex structure, easy to cool uneven plastic parts, through the "grafting" way, has been CNC machining on the simple matrix printing molding of complex structure, with the shape of the cooling channel core cavity.

- The use of 3D printed breathable mold, good air permeability, casting surface profile is clear. Filling resistance, power and die force are effectively reduced. Mold weight can be reduced by 1/3, save material. The size of the breathable mold can be customized according to customer requirements, and different processes can be flexibly configured based on special functional parts. The breathable mold can be made for the trapped gas area of the mold to save cost. The breathable mold can solve the problems such as trapped gas, water groove, incomplete filling and burr during injection molding, reduce the loss in production, and eliminate trapped gas to reduce the damage to the mold.

Technical advantages

Lejia has been deeply engaged in additive manufacturing industry for more than 20 years, and has obtained the technology transfer and authorization of the earliest SLM equipment R&D team of South China University of Science and Technology in China. Lejia is committed to creating an international leading metal 3D printing solution provider, with outstanding application advantages and obvious service benefits in the field of mold manufacturing. Mainly reflected in:

Mature technology

Nearly 20 years of technology accumulation, product features complete, stable quality, mature technology

Stable performance

Multi-module integration ensures excellent quality and stable performance

Efficient molding

Efficient molding, superior performance, shorten the production cycle

Dimensional diversity

Large size molding, meet all kinds of molding needs, without fear of complex structure

Low manufacturing cost

Automatic digital production, optimize parts structure, lightweight, reduce manufacturing cost

Case

Related products

Learn more from our experts

We are committed to accelerating the development of advanced applications and innovative additive manufacturing solutions. If you are just beginning to explore additive manufacturing or have some experience in additive manufacturing, our experts can help you take it to the next level, no matter what stage you are in.

VenicePlease fill in the requirement information

(We will contact you as soon as possible)

Recommend the article

-

2021/04/06

2021/04/06

Why do mold enterprises purchase equipment from metal 3D printing equipment manufacturers?

Learn More>

-

2021/03/08

2021/03/08

Reasons for the continuous expansion of the application of brand metal 3D printers

Learn More>

-

2021/02/20

2021/02/20

What are the reasons for the good production effect of brand metal 3D printers

Learn More>

-

2018/12/31

2018/12/31

Goodbye 2018, hello 2019!

Learn More>

You may be interested

-

Metal 3D printer

Metal 3D printers utilize SLM (Selective Laser Melting) technology to meet the needs of a wide range of applications, from rapid prototyping to tool manufacturing to final production

Composite equipment

Using DED (directional energy deposition) technology, the equipment can meet the requirements of high precision, high quality and efficient forming and in-situ repair of complex structures.

Database

Learn how industries are using 3D printing to speed up r&d and innovation. More product pages, success stories, industry insights and customer interviews welcome to explore

Other industry solutions

Follow lei Jia's official wechat

Here you can find more metal 3D printing technology solutions for aerospace, industrial applications, medical, mold manufacturing and educational research, jewelry customization and other industries, as well as more 3D printing industry information and promotion information.

Contact us

中文

中文

粤公网安备 44010302000658号

粤公网安备 44010302000658号